The most common inorganic filler in modern coatings is Aluminium Hydroxide. If you’ve ever wondered why this bland‑looking white powder shows up in everything from automotive finishes to household wall paint, you’re about to get the full picture.

What is Aluminium Hydroxide?

Aluminium Hydroxide is a naturally occurring mineral often derived from bauxite ore. Its chemical formula, Al(OH)3, gives it a layered crystal structure that makes the particles flat and plate‑like. This morphology is why it behaves like a perfect extender in paint mixes.

Why Paint Makers Choose It

Aluminium Hydroxide brings three core benefits to a coating formulation:

- Cost efficiency - it’s cheaper per kilogram than many specialty pigments.

- Opacity control - the flat particles scatter light without adding colour.

- Rheology balance - it helps the paint flow evenly during brushing or spraying.

Because it’s chemically inert, it won’t react with most organic binders, keeping the colour and durability of the final film intact.

Key Physical Traits That Matter

When engineers talk about filler performance, they focus on a few measurable attributes:

- Particle size - usually 1-5 µm for coating grades.

- Specific surface area - around 15 m²/g, enough to influence viscosity without thickening the mix.

- Refractive index - roughly 1.50, close to that of many polymers, which minimizes colour shift.

These numbers make Aluminium Hydroxide a “neutral” extender that can be added in large volumes (up to 30 % of the solid content) without jeopardising gloss or hardness.

Roles in Paint and Coating Formulations

Beyond being a cheap filler, Aluminium Hydroxide serves several technical functions:

1. Filler/Extender

It dilutes expensive pigments like Titanium Dioxide while preserving hiding power. This lets manufacturers hit target price points for mass‑market paints.

2. Rheology Modifier

The plate‑like particles create a “lamellar” network that steadies flow. In water‑borne systems, this reduces sagging on vertical surfaces.

3. pH Buffer

Aluminium Hydroxide can neutralise excess acid generated during curing of Epoxy Resin or Acrylic Resin. Maintaining a near‑neutral pH helps protect metal substrates from corrosion.

4. Corrosion Inhibitor

When used on steel primers, the hydroxide forms a thin protective layer that slows down rust initiation, especially in humid climates.

How It Stacks Up Against Other Extenders

| Attribute | Aluminium Hydroxide | Calcium Carbonate | Talc | Mica |

|---|---|---|---|---|

| Typical Particle Size (µm) | 1-5 | 2-10 | 5-15 | 8-20 |

| Refractive Index | 1.50 | 1.59 | 1.54 | 1.58 |

| Cost (USD/kg) | 0.70 | 0.45 | 0.55 | 1.20 |

| Primary Function | Filler & pH buffer | Bulk filler | Matte finish | Flake‑type pigment |

While Calcium Carbonate wins on price, Aluminium Hydroxide’s buffering ability and flatter particle shape give it an edge in high‑performance coatings where durability matters more than raw cost.

Formulation Checklist for Best Results

- Pre‑disperse the powder in the carrier solvent to avoid agglomerates.

- Target a dosage of 10‑30 % of total solids depending on the desired gloss.

- Match the pH of the mix to 7‑8 when using epoxy or polyurethane binders.

- Combine with a small amount of Zinc Oxide for added UV stability if the coating will be outdoors.

- Conduct a quick viscosity check (e.g., DIN 4-6 cP) before scaling up.

Common Pitfalls and How to Avoid Them

Even a humble filler can cause trouble if handled poorly:

- Over‑filling - exceeding 30 % can lead to chalking and reduced adhesion.

- Poor dispersion - clumps create weak spots that appear as pinholes after curing.

- Incompatible binders - some water‑borne acrylics with high ionic strength may cause premature flocculation; a small surfactant dose solves this.

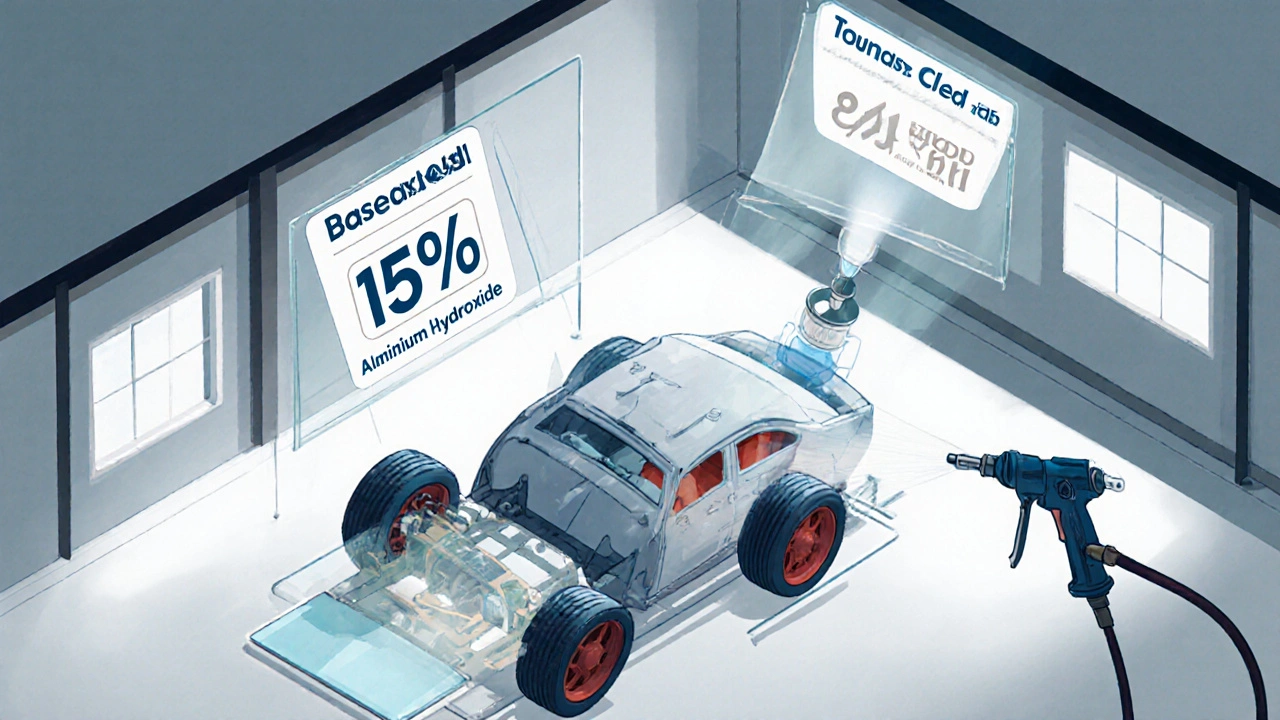

Real‑World Example: Automotive Clearcoat

One major car maker uses a two‑stage system. The basecoat contains 15 % Aluminium Hydroxide to cut the cost of Titanium Dioxide while retaining the required opacity. The clearcoat adds another 8 % to improve flow and act as a buffer against the acidic amine curing agents in the underlying primer. Field tests showed a 12 % reduction in sag defects and a 7 % increase in corrosion resistance over a control formulation that omitted the hydroxide.

Quick Recap

- Aluminium Hydroxide is a cheap, inert filler with flat particles.

- It improves opacity, rheology, pH balance, and corrosion protection.

- Best used at 10‑30 % solids, pre‑dispersed, and paired with compatible binders.

- Compared to calcium carbonate, talc, and mica, it offers unique buffering and particle‑shape benefits.

Can Aluminium Hydroxide be used in water‑borne paints?

Yes. Its low solubility keeps it stable in aqueous systems, and it helps maintain a neutral pH that protects the polymer matrix.

What particle size should I target?

For most coating applications, 1‑5 µm provides a good balance between opacity and flow. Finer grades can increase viscosity unnecessarily.

Is it safe for indoor use?

Aluminium Hydroxide is non‑toxic and approved for indoor environments. It’s even used as a flame retardant in some building materials.

How does it affect drying time?

Because it doesn’t react chemically, it generally won’t slow down the cure. However, excessive loading can trap solvents and slightly lengthen drying.

Can I replace it with calcium carbonate?

You can, but you’ll lose the pH‑buffering action and the flat‑plate morphology that improves flow. If cost is the main driver, calcium carbonate works, but you may need a separate dispersant.

Deborah Galloway

October 25, 2025 AT 12:24I totally get why the chemistry of aluminium hydroxide can feel a bit overwhelming at first.

It’s actually one of the unsung heroes in the paint world, quietly doing its job without demanding the spotlight.

Because the particles are flat and plate‑like, they create a smooth, even surface that helps the paint spread nicely.

That morphology also means you get great opacity without adding any unwanted color.

From a cost perspective, manufacturers love it because it’s cheaper than many specialty pigments.

But the real magic lies in its ability to act as a mild pH buffer during curing.

When you’re working with epoxy or acrylic binders, that buffering can protect metal substrates from corrosion.

In water‑borne systems, the lamellar network formed by the filler reduces sagging on vertical walls.

If you pre‑disperse the powder properly, you’ll avoid those dreaded clumps that turn into pinholes later on.

Sticking to the 10‑30 % solids range ensures you keep the gloss and hardness you’re after.

And pairing it with a tiny touch of zinc oxide can give you that extra UV stability for outdoor projects.

I’ve seen labs report a nice 12 % reduction in sag defects when they added the right amount of aluminium hydroxide.

That same study also noted a modest boost in corrosion resistance, which is a win‑win for automotive clearcoats.

So while it may look like just a bland white powder, it’s actually a versatile tool in the formulators toolbox.

Feel free to experiment with it in your own mixes-you might be surprised at how much it can improve performance.

Charlie Stillwell

November 2, 2025 AT 13:51Look, the whole "cheap filler" narrative is just a veneer for a deep‑seated industrial economics game. Aluminium hydroxide’s lamellar architecture provides a rheological scaffolding that’s practically a textbook case of shear‑thinning behavior 😤. If you don’t grind the particles to that 1‑5 µm sweet spot, you’re basically courting viscosity spikes and sagging nightmares. The cost‑benefit matrix only makes sense when you factor in the lifecycle corrosion mitigation – otherwise you’re just another pigment pusher. 🚀

Ken Dany Poquiz Bocanegra

November 10, 2025 AT 16:18The buffering action of aluminium hydroxide often slips under the radar, yet it’s a silent safeguard for polymer integrity. By keeping the pH neutral, you avoid premature degradation of acrylic binders. Simple, effective, and scalable – that’s the sweet spot for modern coating tech.

Tamara Schäfer

November 18, 2025 AT 18:44I totally agree with the points about the lamellarr shape but also think the article missed the practical side of mixing. In my lab we often see clump formation even when we pre‑disperse, probably cause of humidity levels. Small tweaks like adding a tiny surfactant can make huge diffrence, trust me! Also, typos in datasheets can lead to wrong dosage, so double‑check your specs.

Tamara Tioran-Harrison

November 26, 2025 AT 21:11Ah, the age‑old debate of “cheap filler vs. premium pigment”. One might argue that substituting aluminium hydroxide for calcium carbonate is nothing short of fiscal myopia, yet the author glosses over the inevitable trade‑offs with a veneer of sarcasm. One must, of course, consider the philosophical implications of cost‑driven formulation decisions, lest we sacrifice the very essence of aesthetic fidelity. 😏

kevin burton

December 4, 2025 AT 23:38From a formulation standpoint, the author’s checklist aligns well with standard practice. Pre‑dispersion, dosage control, and pH matching are indeed critical steps. Using a modest amount of zinc oxide for UV stability is a sound recommendation, especially for exterior applications. Maintaining viscosity within DIN 4‑6 cP ensures the coating can be applied without sagging.

Max Lilleyman

December 13, 2025 AT 02:04Honestly, most of these “technical” articles are just marketing fluff. If you aren’t scrutinizing the data sheets, you’re blindly trusting corporate spin. The real issue is that manufacturers hide the actual particle distribution to make their products look better. 🙄

Buddy Bryan

December 21, 2025 AT 04:31While it’s easy to dismiss the data as marketing, the empirical evidence of reduced sagging and improved corrosion resistance can’t be ignored. The lamellar network formed by aluminium hydroxide truly does enhance flow dynamics, especially in high‑solids systems. It’s a practical advantage worth considering for large‑scale production.

Jonah O

December 29, 2025 AT 06:58Don’t you think it’s suspicious how quickly these “studies” appear just when a big chemical conglomerate pushes a new filler? There’s often a hidden agenda to shift market share away from traditional carbonates. I’ve heard whispers about undisclosed testing protocols that favor aluminium hydroxide. Keep your eyes open.

Aaron Kuan

January 6, 2026 AT 09:24Aluminium hydroxide just works.

Benjamin Sequeira benavente

January 14, 2026 AT 11:51Exactly! You’ve hit the nail on the head – no need for endless debates when the performance speaks for itself. Keep experimenting and you’ll see the benefits roll in fast. 💪

Abby W

January 22, 2026 AT 14:18Nice roundup! 😁 I’d add that a quick torque test after curing can verify the corrosion‑inhibiting effect. Also, don’t forget to calibrate your viscometer before each batch – consistency is king.